Hybrid ZF8 Swap - Part One: The Hardware

Modern, clutch to clutch automatic transmissions such as the ZF8HP family are able to provide a substantial performance and efficiency advantage to even legacy automotive powertrains, while improving driving dynamics substantially. In this example, we’re swapping an E93 335i’s 6 speed manual gearbox for a ZF8, with the end goal of developing a TCU to be able to use an H-gate shifter and clutch pedal when a manual-like experience is desired, while also retaining its ability to behave as the automatic transmission it was designed to be: the best of both worlds.

The first order of business, and what we’ll cover in this article, is the physical hardware swap. Due to the nature of this particular cars powertrain (an N54 with big turbos, making over 500ft-lb), the weaker HP45 was deemed to be insufficient for the application. Unfortunately, there is not a commonly available (in the US) 8HP70 with the correct bellhousing to bolt up to an N series engine directly, so we had a few options:

Import an HP70 from a European diesel model, and adapt it to the N54 using an aftermarket adapter plate.

Abandon the idea of an HP70, settle for an HP45, and see how long it holds up in our application.

Buy an upgraded HP45, which is prohibitively expensive.

Take a risk and commit to pioneering the use of the ActiveHybrid5 gearbox - the ZF8P70H. This gearbox does natively bolt up to the N54, but poses other technical challenges.

Ultimately, we settled on option 4. There’s nothing quite like a good adventure after all.

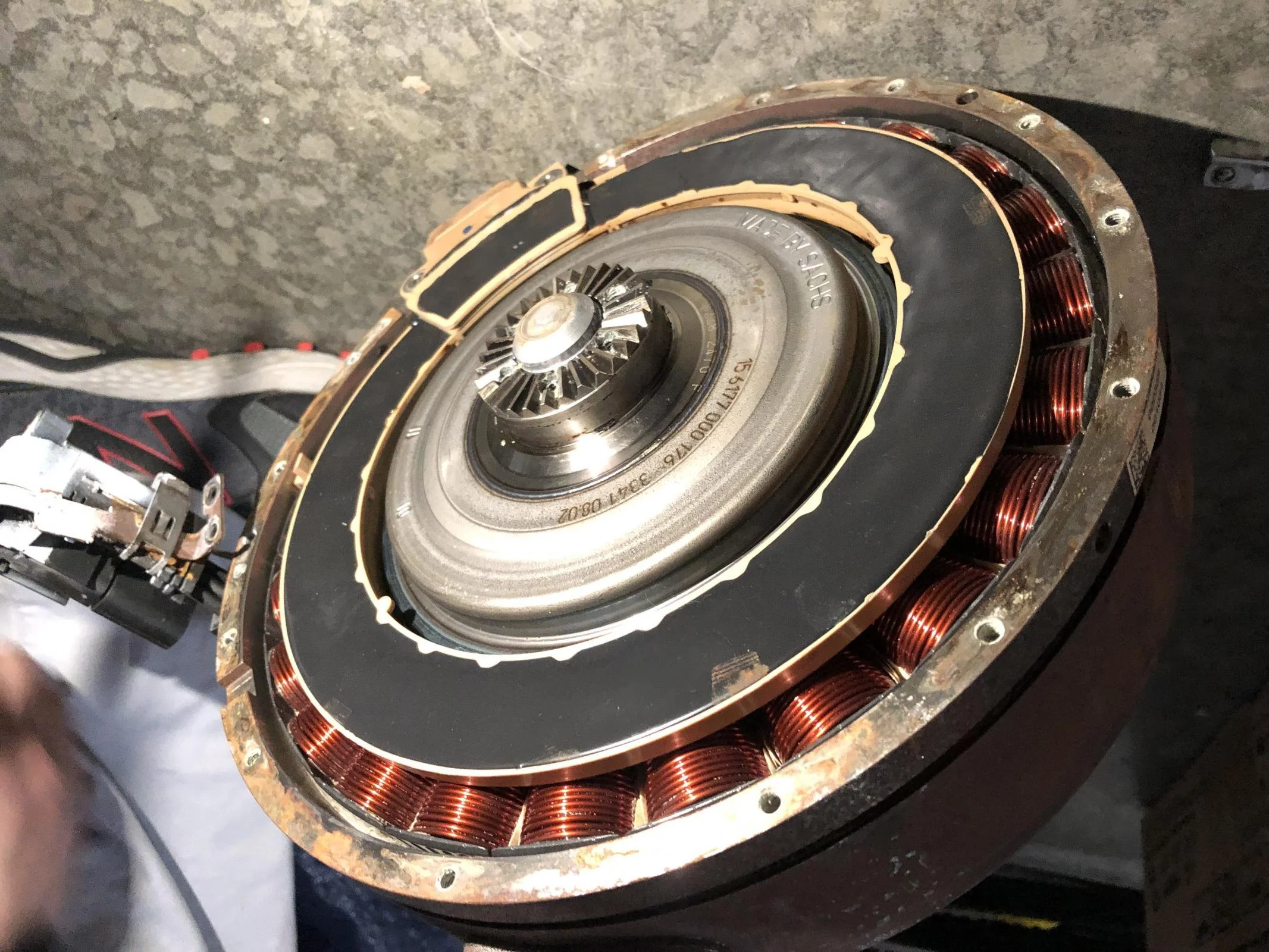

The use of an 8P70H posed a few immediately obvious challenges- and two others which took a while to learn. First, there’s no torque converter (hence it being an 8P and not an 8HP - the H denotes hydraulic coupling, and the P denotes planetary). In the 8P, the bellhousing is instead occupied by a large electric motor with an integrated decoupling element. Whenever full EV mode is active, the decoupling element unlocks and breaks the mechanical connection between the electric motor (which is coupled to the gearbox input shaft), and the internal combustion engine. In theory, this decoupling element could also be used for take-up (pulling away from a stop) but ZF elected to use a more robust option instead - which brings us to the internals.

The electric machine which goes in place of the ZF8s standard torque converter, for hybrid applications.

The 8P has a number of internal modifications compared to a standard HP70. First, its not quite an HP70…or an HP45. Compared to the standard HP45 which comes paired to the N54s successor (the N55), the 8P70 has additional clutch plates on a few elements, while others remain unchanged. By far the biggest upgrade for this particular gearbox is the B clutch - because it also serves as a launch element, and must tolerate slipping under potentially large torques at every take-up/launch. The integrated decoupling element in the “electric machine” (as BMW calls it), is quite small due to space constraints and is likely unable to withstand the abuse of a turbocharged 6 cylinder which is capable of 300ft-lb of torque as low as 1300rpm. In order for the B clutch to withstand this use case for an acceptable lifetime, it has a substantially upgraded cooling system and physical construction. The steels, for example, are 3 times as thick as those found on the regular 8HP. There are many additional (and large) cooling ports integrated into the housing, and the pressure plate has been substantially reinforced in order to load the clutch surfaces as desired. The upgrades, while very welcome, require a unique transmission calibration in order for the gearbox to operate smoothly and with an acceptable lifetime.

This fancy decoupling element and launch clutch combo comes with one additional issue. Being a hydraulically controlled transmission, the clutches are applied by oil pressure generated by the gearboxes mechanically driven hydraulic pump. In a traditional automatic transmission, this pump is rigidly coupled to the engines crankshaft through the torque converter body. However, in the hybrid ‘box with its normally opened decoupling element, there’s no existing method of engaging the decoupling element to spin the hydraulic pump to create the pressure to engage the decoupling element in the first place. Now, maybe they could have used a wave plate system which applies an amount of clutch preload with no hydraulic pressure (enough to spin the pump), which is then hydraulically further decoupled or engaged, but ZF wanted to maintain the highest level of modularity as possible, and modifying the transmissions input shaft and valve body to add the additional passages was seemingly too substantial of a change - especially when the chosen solution to this issue comes with its own benefits. So, instead, ZF installed an electric oil pump in the transmission pan which can be activated in order to provide full hydraulic pressure to the gearbox, even when nothing is spinning. A major benefit of this integration is the ability of the vehicle to seamlessly pull away from a stop in EV only mode, with no need to modulate clutch slip and manage rising hydraulic pressure during the initial take-up.

Control of this pump, and the substantial mass of the electric machine which would be of no benefit in our application, drove us to find a different solution: simply replace the electric machine with a traditional torque converter from an N55 powered car. Because ZF is great, it bolts right up without fuss, and works exactly as intended. The electric hydraulic pump was left in the transmission pan, but is unused. If increased oil capacity and reduced gearbox mass were a priority, we’d likely have machined a block off plate for its hydraulic connections and removed it, but we didn’t see that as worthwhile.

The auxiliary electric oil pump, used for take-up.

There’s one more change too - one which was not known about in the aftermarket at the time, and one that caused the general consensus regarding the attempted use of an 8P to be that “it won’t work, the input shaft doesn’t spin, even with a torque converter installed”.

The input shaft speed sensor. As the “electric machine” contains a precise resolver which the OEM TCU is able to monitor in order to determine input shaft speed, there is no direct need for the dedicated input shaft speed sensor used on non-hybrid boxes. For a reason unknown to me, ZF elected to repurpose this speed sensor to read the rotational speed of an intermediate element in the gearbox. This isn’t immediately obvious while looking at the speed sensor or gearbox, as the 8HP input shaft speed sensor works by reading a magnetic toothed wheel on the P2 planet carrier…through another concentric rotating drum. As the outer rotating drum is aluminum, it does not substantially interfere with the signal from the magnetic wheel, and thus its possible to easily measure the speed of internal components - externally.

An image of the cutout in the transmission case through which the speed sensor reads the input shaft speed. Note the smooth, non-ferrous and non-toothed drum which is invisible to the sensor - allowing the internal reluctor wheel to be measured.

For the 8P , one simple change was made: instead of a magnetic wheel being equipped on the P2 planet carrier, it is instead a standalone piece which fits into the drum and spins along with it. Determining this wasn’t particularly straightforward, but we were pleasantly surprised to pull the gearbox apart and learn that our hypothesis was correct. The most obvious indication of this difference was the behavior of the input shaft speed sensor. By calculating the theoretical rotating speed of the drum in different gears (for example, in 6th gear the drum rotates at input shaft speed, which is also equal to engine speed with a locked torque converter), and noticing the exact correlation with what the TCU was seeing, we were pretty confident in our hypothesis.

Our solution was to open the gearbox, remove the trigger wheel that is splined to the drum, and replace the OEM 8P P2 planet carrier with one from an 8HP that has the needed integrated trigger wheel - in this case, it came from a Jaguar 8HP70. It fit perfectly without issue, a real testament to the brilliant engineering behind the ZF8.

The toothed magnetic wheel, unique to the hybrid 8P70H, which interfaces with the outermost drum which can be seen in the photo background.

With all of that said and done, the hardware works. Initially using an off-the-shelf transmission controller designed for traditional ZF8 swaps and some extensive time tuning the controller for our unique configuration, we were able to get a car that drove well - at least as well as the chosen standalone TCU could allow. In order to realize the goal of H pattern shifter compatibility, a natural feeling clutch pedal, and seamless operation in automatic mode, we decided that developing our own TCU was the only option. The next articles will cover that process in detail - and where it is today.